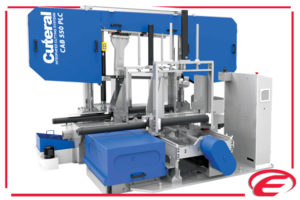

Double Column Hydraulic Band Saw Machines

Full Automatic Double Mitre Band Saws

Full Automatic PLC Control Double Column Hydraulic Bandsaw Machines

Cuteral – We use our knowledge, experience and technical background for community awareness, and we develop new technologies that our industry and the global economy need.

When the head of a band sawing machine travels down on 2 posts, it is called a Dual Column type of bandsaw. The terms dual-column, dual-post, twin-post are used interchangeably. This design is what we use in industry for cutting large parts while keeping the blade as straight as possible while the head is descending during the cut.

This design keeps the blade from moving or walking. Our full range of double column Bandsaws are available in a large selection of sizes to meet your companies requirements for cutting large pipe and structural shapes.

The Dual column bandsaw range will be able to set the speed ranges available to you’re your specific application . Our displays allow the operator to adjust and monitor all parameters for manual or automatic functioning.

Cuteral build energy-efficient rational systems which are stable on production speed and standardization, and economic on minimizing production costs; and we provide fast and secure solutions for production stage and after-sales support needs.

- Both columns are ground and chrome-plated

- Delivers uniform feed force on bandsaw blade

- Provides shorter, more efficient cutting paths

- Superior to swing frame and vertical systems

- Bowframe is guided by a rugged, large diameter dual column assembly

SIMPLE AND POWERFUL WITH A HEAVY DUTY HEART!:

THOR 860: DOUBLE COLUMN SEMI-AUTOMATIC BAND SAWING MEP MACHINE, suitable for metals, ferrous & non-ferrous materials to cut solid / structural – section round / square / rectangular / hollow tubes at 0°

Machine designed to suit bi-metal as well as TCT (carbide tipped) blade.

– Electrical control panel with push button, emergency stop button, main isolator, PLC, VFD, step down transformer, auxiliary contractor, cable connector and connector with fuses.

– Hydraulic valve and feed pressure adjustment valves are fitted on control panel for easy operation.

– Moving blade guide mounted on rigid construction slide way arrangement which is attached to the moving vice to make machine foolproof and automatically adjust as per the bar size.

Some other features of the Double Column Band Saw include:

- STABILITY

– Heavy duty steel welded structure – torsion free construction to cut vibrations giving max stability to the saw and consequently accurate cuts and longer blade life

- VICE

– Split vice for rigid clamping and burr free cuts: split main vice helps in holding the job on both sides of cutting.

- BLADE GUIDES

– Blade guides preciously machined and fitted with replaceable carbide pads and anti-friction bearings for smooth up-down movements of cutting head (blade).

- PRODUCTIVITY

– Electric motor is coupled to the gear box. Saw Blade speed change through variable frequency drive (INVERTER) for optimum productivity and tool life.

- SENSOR

– Hydro Mechanical sensor to adjust feed without operator involvement depending upon material type, hardness and cross – section

- FEED CONTROL

– Infinitely variable Feed Control Valve. Hydraulic automatic feed regulation to adjust in automatic head feed rate according to size and hardness of material.

Interested in finding out more about our Pressbrake Machines? - Get In Touch

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.