Engineering Machinery and services offer not only Flatbed cutting systems, but also known as 2D cutting, nonetheless, it is the most common application in laser cutting Metal for our new and current customers. Fiber lasers have established themselves worldwide as the dominant laser beam source. 2D laser cutting systems process flat material of various thicknesses made of steel, stainless steel, aluminum, or non-ferrous metals with great accuracy and high cutting speed. Our Fiber Laser machines which are used for laser cutting are equipped with a total of three axes: two positioning axes for traversing the desired cutting contour and a Z-axis for adjusting the distance between the workpiece and the cutting head.

TowerMak

The TOWERMAK system is equipped with devices, such as:

• An automatic separation of the metal sheet from the pile

(heap): This is a function carried out from a magnet and one

of the suction cups that acts on the corner of the metal sheet

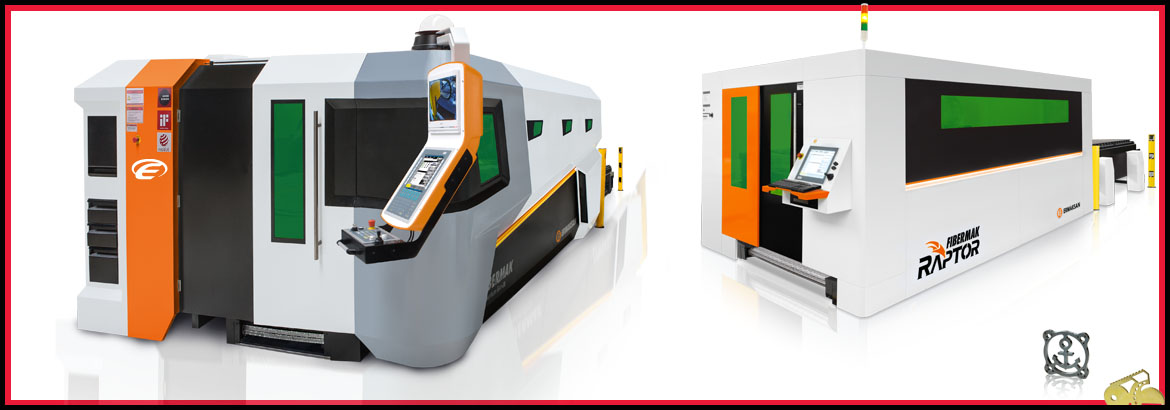

Fiber Laser | G-Force

Fibermak G-Force is designed with the servo motor concept, A machine equipped with a servo motor may reach up to 46 acceleration with its rigid bridge as a result of dynamic analyses performed and its perfect design. Thanks to the high acceleration that provide great advantages while switching between parts, production time is decreased and efficiency is increased by 15% per hour in average. The more complex the part to be processed, the greater the productivity.

Produced by using long-lite and high duality components together with its strong body structure, Fibermak G-Force is designed to operate continuously and precisely even under the most severe conditions.

Fiber Tube

Ermaksan Fibertube — CUTTING LASER IDEAL SOLUTIONS FOR TUBE AND PROFILE PROCESSING ERMAKSAN introduces a full automatic tube cutting machine with Fibertube. With the automatic tube loading section, the tubes loaded as bundle, are separated and a tube is made ready to be loaded into the chucks. The tube loaded may be processed either as short pieces or full length as desired. The tubes processed with high precision and minimum amount of waste thanks to fiber laser cutting technology are transferred to the unloading section and collected in the part collection case. smart factory solutionIf you are a business looking to expand or diversify, the Hawk opens up new opportunity in different markets.

Fiber Laser | Raptor

The Raptor uses special optical fiber as the active medium, the thickness of only a few micrometres producing a beam of high performance, optimal quality.

Advantages FIBER laser machine – Raptor:

Fiber is the fastest laser cutting process thin sheet.

By cutting laser results in a higher quality cut edge compared to other options.

It obtained a smooth cut without burrs or rough.

Reflective materials such as aluminum, copper or brass can be cut easily.

It obtained an excellent surface quality on carbon steel sheets.

Side Loader

Introducing the NEW Ermaksan Fibermak SL side loading fiber laser. The new side loading design is the right choice for workshops with limited space, without compromising the standards and quality of the Fibermak Momentum Gen-3 G Force.

- Space saving design.

- Standards and quality of Fibermak Momentum Gen-3 G Force.

- Productivity is increased on average 15% per hour.

Interested in finding out more about our Laser Machines? - Get In Touch

Increasing its production efficiency in laser cutting technology with our CNC Fiber Laser Machinery we can provide the very best solutions to meet the requirements of the industry with various machine models it has introduced to the market. In addition to offering customized solutions to customer requirements, it also contributes to smart manufacturing processes by developing machines suitable for automation. With our industry 4.0 solutions which shall provide greater flexibility in production processes, factories are much smarter, and the manufacturing operations are more digital and traceable now.

Our CNC Fiber Laser Machines & the latest software technologies are used in many stages of the manufacturing industry, particularly in automotive and aerospace, contributes to the efficiency and sustainability of production by meeting customer expectations in terms of high precision and cutting speed, minimum roughness and long-term operating performance.

By continuously monitoring new trends and customer expectations and designing and producing environment friendly and energy saving machines with advanced technology and high added value, Ermaksan is moving forward with its stakeholders on the way to sustainable growth by taking strong steps to the future.

CNC LASER MACHINERY | CNC Fiber Laser Machinery

Laser cutting is a thermal cutting process for processing sheet metal. The laser beam is created by the laser source (resonator), conducted by a transport fiber or mirrors in the machine cutting head where a lens focuses it at very high power on a very small diameter. This focused laser beam meets the sheet metal and melts it.

Engineering Machinery with IPG Lasers | uses two types of laser sources: Fiber laser and CO₂ laser.

From compact fiber CNC laser cutting to side loading laser cutting, our range of CNC fiber laser cutting machines are designed to make outsourcing a thing of the past. With years of experience and knowledge of the industry and an in-depth understanding of a wide range of applications, our sales team strive to recommend the most suitable machinery for your specific requirement.

Fiber laser

Fiber lasers are the most efficient way in laser cutting. The laser beam is created by an active fiber and transmitted over a transport fiber to the machine cutting head. Fiber lasers are significantly smaller than CO₂ lasers and generate twice as much power from the same amount of current. A fiber cutting system is primarily suited for processing thin to thick sheet metal from steel and also non-ferrous metals (copper and brass).

CO₂ laser

A CO₂ laser uses a gas mixture to create the laser beam. The necessary high voltage in the resonator is created with the help of wear-free semiconductor excitation modules. Our machines relies on such modules since they are smaller, more efficient and reliable than traditional solutions.