Waterjet Cutting Machine Solutions

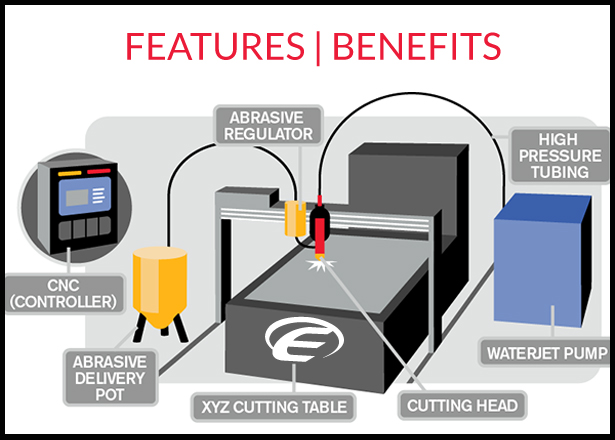

Features & Benefits of Water Cutting

HyPrecision WaterJets

There are several different ways to cut metals. For small to medium operations that value versatility and economy over speed and precision, cnc waterjet cutting systems are one of the best options

Waterjet cutting has really come to the forefront of manufacturing in recent years because of its versatility. There are an array of reasons to choose waterjet cutting over other methods, and they aren’t all about the actual cutting control. Improved efficiency in processes and reduced wastage and costs also factor highly, which by default leads to improved customer service.

Hypertherm HyPrecision waterjets were engineered using Advanced Intensifier Technology (AIT). By rethinking the way the intensifier pump works, we were able to make it work harder, last longer, and require less service time. AIT, it’s what makes Hypertherm HyPrecision waterjets more cost effective than any other waterjet in the world.

When creating the optimal waterjet system, Hypertherm did not limit its thinking to the intensifier. We wanted to create a streamlined experience that combines an intuitive operator interface with advanced system monitoring. The outcome is a powerful software package that arms operators with system information that maximizes uptime.

In addition to producing exceptional fine-feature cut quality, waterjet technology can handle a wider variety of materials and thicknesses than any other cutting method. Whatever your waterjet application – from small prototype jobs to 24/7 manufacturing – there’s a HyPrecision™ cutting machine to meet your needs.

Result: the most reliable, most cost-effective waterjet in the world, and a pump that:

- Delivers optimum cut quality

- Is easier to service

- Lasts longer

- Is easier to access

- Requires less routine maintenance

WaterJet Cutting Typical Applications:

Waterjet technology produces excellent fine-feature cut quality with low edge angularity, no heat-affected zone, a narrow kerf, and virtually dross-free cutting. It is widely used to cut stainless steel and aluminum, but its flexibility also makes it useful for other materials.

– Shape cutting of ¼” and thicker aluminum

– Net size cutting of ½” and thicker stainless steel

– Blank cutting parts for final machining

– Short run lots of sheet metal parts – Screen cutting

– Converting plate stock to bars

– Precision cuts in ½” and thicker mild steel – Hardened materials

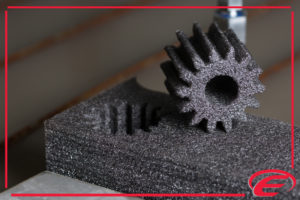

– Intricate shapes in delicate materials

– Custom shims in stainless steel and exotic materials – Tube cutting

Key Benefits of WaterJet Machines

- AUTOMATIC NESTING

Automatically nests parts for economical sheet usage.

- AUTOMATIC LEAD IN/OUT

Software automatically applies lead ins/out for quicker programming.

- PART IN PART NESTING

Nest parts in scrap areas to fully utilise the sheet.

- COMMON-LINE CUT

Cut along shared edges of parts.

- PARAMETRIC SHAPE LIBRARY

Over 80 configurable shapes.

- JOB REPORTS

Export job reports displaying scrap percentage and cutting times.

Interested in finding out more about our Plasma Machines? - Get In Touch

As technology gets more innovative and cutting edge, so do customers machining requirements. Extremely complex designs, shapes and patterns can now be manufactured using waterjet cutting. There are no drill holes required at starting points meaning much sharper corners can be cut as well more curves.

Traditional cutting and milling machines manufacture square shapes by profiling with a cutter, leaving a radius in the corner and then remachining multiple times until that radius becomes square. Waterjet cutting removes that need for multiple rounds of machining – it just cuts square! The time spent machining is reduced with no need for further finishing actions once the cutting is complete.

1. No material limitations

Waterjet cutting is versatile applicable, cutting nearly any material; composites, plastics, metals, glass, stone or rock, ceramics, and rubber. With the addition of a granular abrasive, a waterjet cutting machine can perform quality cuts on materials up to 200 mm thickness.

2. No Heat Affected Zone (HAZ)

A major advantage of waterjet cutting is that no heat affected zone (HAZ) occurs due to its cold cutting method. Not only does cold cutting enable clean cuts, but also increases the operators’ safety significantly by eliminating the risks of burns.

3. No material distortion

Through its cold cutting method, the heat exposure can be bypassed, which is especially critical for materials like metal, leading to a fine cut without distortion in the material. This results in a smooth and burr-free cut.

4. No additional finishing process

The immediate high cutting quality ensures a precise result, avoiding an additional finishing process. This significantly accelerates the cutting process and saves time, increasing the overall efficiency.

5. No hazardous waste

The growing importance of environmentally friendly processes throughout the industries is becoming more apparent. A significant advantage of waterjet cutting is that it does not create any hazardous waste in the form of fumes and gases, unlike other cutting technologies.

Our wide range of products and services across multiple industries combined with our expertise means that customers have just one point of contact for their whole project, from start to finish.

Why Engineering Machinery & Services ?

INDUSTRY SPECIALISTS

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

COMPREHENSIVE RANGE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

BRAND CONFIDENCE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

WE COME TO YOU

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

UNBEATABLE SERVICE

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.

CONSUMABLES

Our comprehensive range of new and used sheet metal, fabrication, sawing and engineering machines includes over 800 models, and is complemented by our carefully selected consumable products.