Hypertherm Plasma – Call Northern Ireland – 028 2934 8458 or Ireland 01 4571399

Reduce time consuming and costly grinding

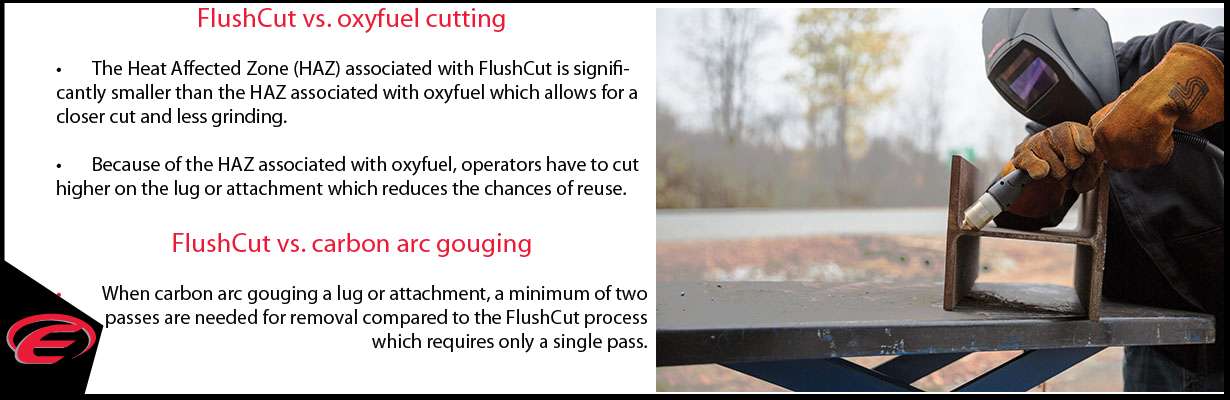

Close cutting for the removal of lugs and other attachments has typically been performed via oxyfuel cutting or carbon arc gouging, followed by labor intensive grinding. FlushCut for Powermax plasma systems provides a new, more efficient process for challenging removal applications

Flushcut | Hypertherm | Consumables

Introducing the new range of Hypertherm Flushcut consumbles available for Hypertherm Powermax systems (105&125 only)

2017-Engineering Machinery & Services

Call us today to arrange a demo , The angled nozzle of FlushCut consumables reduces secondary grinding by leaving minimal residual material

Also , The 45 degree angle of the FlushCut arc allows for lugs and attachments to be removed with a flat bottom, increasing the

And alot more operators know and tell us the way flat on the shield helps guide operators avoid digging into the base plate, reducing the need for costly repairs

+353 1 4571399 – Engineering Machinery & Services | Ireland

Maximum productivity

- Heat affected zone (HAZ) associated with flush cutting is approximately ten times less than that of oxyfuel allowing you to cut closer to the base material

- Less overall pre-processing time (e.g. no gas setting, purging or preheating) than oxyfuel

- Remove lugs and attachments in a single pass compared to carbon arc gouging which requires multiple passes and additional time

Close cutting applications such as lug and attachment removal are typically done using oxyfuel, carbon arc gouging, or traditional plasma cutting tools. New flush cutting capabilities of Powermax® plasma systems now offer a more efficient process for these operations.

Patented FlushCut™ consumables have been specifically designed to allow Powermax users to cut attachments, lugs, pad eyes and other positive features as close to the base as possible without piercing or damaging the workpiece. An angled nozzle bore design and flat guiding shield enables flush cutting that leaves less than 5mm (3/16”) residual material on the base or work piece, reducing grinding and secondary repair operations.

FlushCut consumables can be used in both mechanized and handheld applications on the following Powermax torches and systems: